What Is The Greyscale, and Why Is It Important?

| Last updated August 26, 2025

Greyscale testing is a method of determining a material’s colorfastness when exposed to accelerated weathering. From the results of the test, a Greyscale score or rating is given to the material. The Greyscale rating is identified based on the amount of change in the sample’s appearance.

As trusted phenolic panel manufacturers for over a century, we have found that this rating is an essential point of consideration and can actually be an important differentiator. Greyscale rating is relevant not only for the purpose of comparing colorfastness, but also because reliable colorfastness can indicate other valuable characteristics in a material.

What is Colorfastness?

Colorfastness Definition

Colorfastness refers to a material’s resistance to color fading or running; it’s the material’s ability to retain its original hue when exposed to the environment. In order to identify the colorfastness of a material, you have to test it against real-life conditions. These conditions need to mimic those which the material will likely face during its expected life cycle.

How to Test Colorfastness

Testing colorfastness means testing the endurance of the material against specific conditions. For an architectural material like exterior phenolic wall panels, these test conditions include accelerated weathering. Colorfastness testing will reveal, for example, if a material will fade when exposed to direct sunlight and UV rays over time, and if so, by how much.

What is Greyscale?

In order for colorfastness testing to be meaningful, there must be a method for standard, comparable measuring. Greyscale testing is that method.

Greyscale Testing

Greyscale testing is the standard method of colorfastness testing. This assessment identifies and rates any effects of the accelerated weathering test by evaluating differences in color shading in a material’s appearance. Ratings are calculated based on the Greyscale as described in ISO 105-A02.

The Greyscale

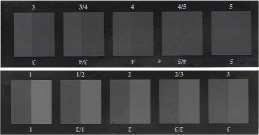

The Greyscale is the tool used to compare the loss of color in a sample by determining a half-step rating from 5 (good; no visual change) to 1 (poor; large visual change). The scale consists of pairs of gray color swatches: one half of the pair is always the same shade of gray, and the other half gets progressively lighter.

Each pair illustrates the shading difference between a control sample and a test sample, and the different pairs correspond to the half-step ratings: 5, 4-5, 4, 3-4, 3, 2-3, 2, 1-2, 1. In this way, the Greyscale ratings provide a colorfastness grade scale. What this means is that there are 9 possible values between 1 and 5.

Source: https://www.caimi.net/wp-content/uploads/2014/10/GREY-SCALE-2.pdf

What is Considered “Good” Colorfastness?

Greyscale testing is a method of determining visual changes (i.e. colorfastness) on a surface sample when exposed to accelerated weathering. Colorfastness, then, is a term related to a material’s score on the Greyscale.

The best possible score is 5, meaning NO visual change; so, the closer to 5, the better. Minimum standards for what is considered good colorfastness, however, will vary by industry.

For example, the industry standard for HPL panels is 3. Fundermax phenolic cladding panels, however, offer superior colorfastness in both interior and exterior applications, achieving a 4-5 Greyscale rating.

Benefits of a High Greyscale Score

A high Greyscale score is an essential point of consideration because good colorfastness reflects other valuable characteristics in a material.

Durability & Longevity

Superior colorfastness is one part of the overall durability and longevity offered by Fundermax phenolic cladding panels. Additional evidence of this durability is the ease of installing panels below 10 feet in high traffic areas without worrying about damage. For installations above 10 feet, durability certainly proves valuable in not having to hire a team to repair less durable panels at precarious heights.

When discussing durability and longevity, it is important to remember that UV exposure can cause otherwise tough wall panels to fade if they are not of the highest quality. In addition to checking a product’s Greyscale score, be sure to note if a manufacturer’s warranty only covers their product’s durability at certain sun exposures. (Fundermax warrants every phenolic panel in any location at every angle.)

Low Maintenance

Closely tied to high durability is low maintenance. An impact-, weather-, and scratch-resistant panel will certainly require less maintenance than a weaker material. But, required maintenance will also be largely impacted by a material’s colorfastness.

There are significant savings to be found when you don’t have to treat or re-paint surfaces – yes, even exterior walls exposed to the elements. Consider: with virtually no maintenance, even when exposed to high traffic, precipitation, and UV rays, it will have very minimal change over time with our 4-5 greyscale rating.

Usability of Double-Sided Panels

Fundermax offers double-sided phenolic resin panels. This means that if a double-sided cladding panel becomes damaged beyond repair, it can be flipped to expose the other side instead.

The overall demand for phenolic panels in the United States is on the rise for many reasons, including all that we’ve discussed above. Be sure that you leverage phenolic panels with superior colorfastness and ultimate longevity by working with highly reputable and globally trusted phenolic panel manufacturers like Fundermax. We proudly go above and beyond the standard in our products and our service. Contact us today to discuss your next project.