Exposed vs. Concealed Fasteners With Exterior Phenolic Panels

| Last updated August 26, 2025

A phenolic wall panel system offers architects virtually limitless design freedom with its combination of technical and creative versatility – and part of that versatility is the choice between different fastening systems. Therefore, when specifying phenolic cladding for a project, it’s advantageous for architects to understand how the different commercial fastening systems work and the distinctions between each method.

For example, Fundermax works hard to remove design limitations from the architects we work with, so our phenolic exterior wall panels have four types of fastening systems available: exposed, concealed, Modulo plank system, and Scaleo lap siding.

In this blog post, we’ll focus on key factors to consider when choosing between exposed and concealed fastening systems.

What Are Key Factors to Consider When Selecting a Fastening System?

These two essential considerations should guide your fastening method selection: substructure material and installation cost.

1. Substructure Material

Your substructure material will likely be wood, steel, or aluminum. Here are a few considerations for each.

Wood

-

Wood systems are typically vertical.

-

Wood substructures can have a shorter lifespan.

-

Wood substructures are more accessible and sustainable.

Steel

-

Steel systems are primarily vertical.

-

Not all phenolic panel manufacturers allow steel substructures.

-

Material compatibility can be an issue (hence, not all cladding manufacturers allow it).

Aluminum

-

A 1” extrusion works for most HPL panels.

-

Aluminum systems offer a longer lifespan than wood and steel.

-

All phenolic panel manufacturers allow aluminum substructures.

2. Installation Cost

Concealed exterior fastening systems are more expensive than exposed fastener systems, mainly because concealed systems use more components to get from the face of the wall to the back of our panel. This is consistent regardless of the phenolic panel manufacturer.

What is an Exposed Fastening System?

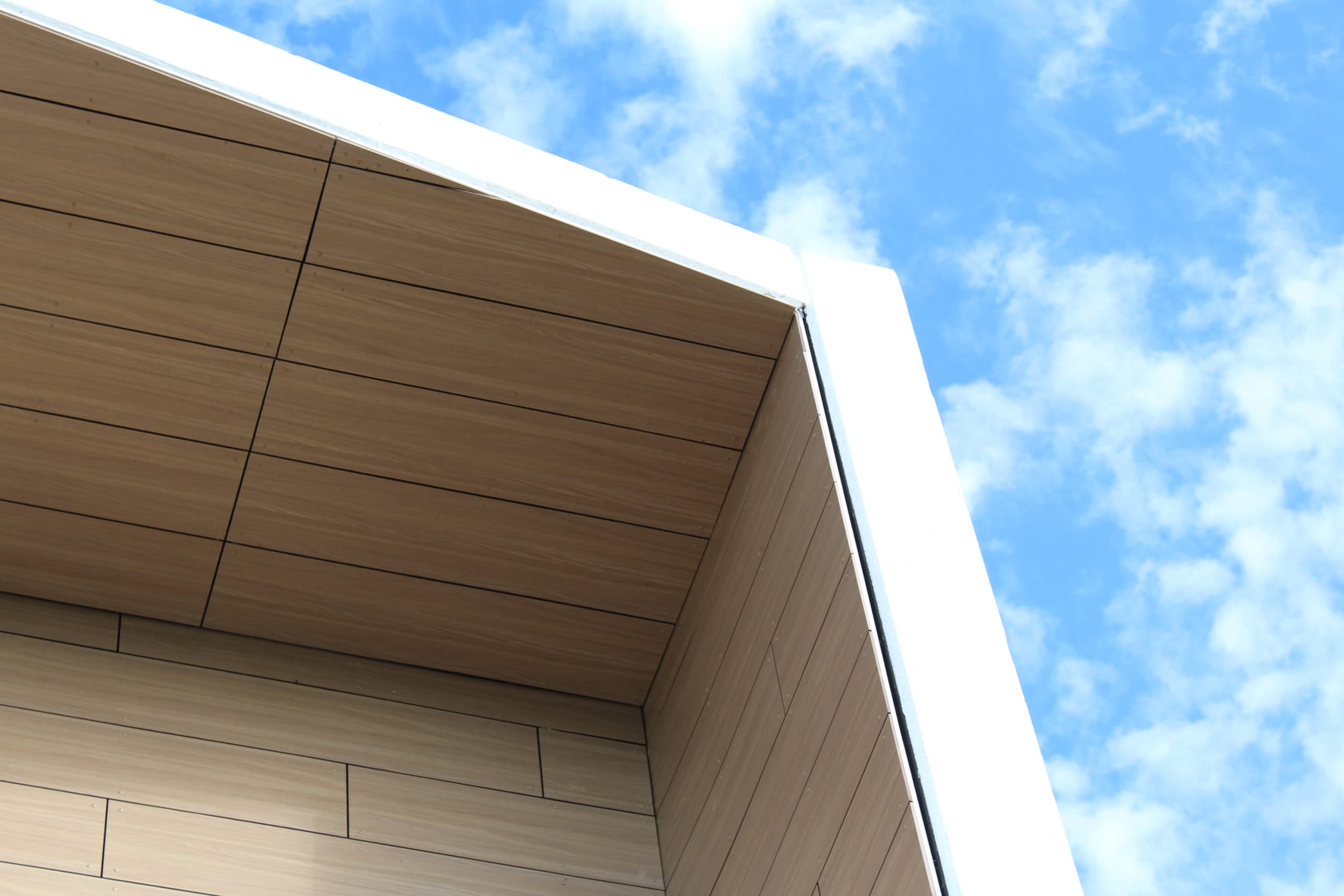

Phenolic wall panels with exposed fastening systems are easy to install, clean, and maintain. Additionally, exposed fastening can be used in horizontal (soffit) and vertical (wall) applications with a wide range of décor options. This is the technical and creative versatility that delivers maximum design freedom, and here, at an economical price point for rainscreen façades, soffits, and other exterior applications.

For example, the Fundermax exposed fastening system uses color-matched screws or rivets to attach phenolic panels to the wood or aluminum substructure; the color-matched fasteners blend right into the façade. However, there is also the option to use polished or black exposed fasteners for a more industrial aesthetic. The design choice is yours.

Examples of Exposed Fastening Systems

The Plaza at Delray Shopping center in Delray Beach, Florida, utilized Fundermax Max Compact Exterior phenolic panels with a woodgrain decor and an exposed fastening system with color-matched screws and rivets.

This Starbucks in West Palm Beach, Florida, originally considered metal cladding for their soffits but ended up choosing durable Max Compact Exterior phenolic panels in a charcoal decor with a color-matched exposed fastening system.

What is a Concealed Fastening System?

A concealed fastening system is a hidden attachment system with no exposed fastening points. With concealed fastened HPL panels, you will choose between a clip and rail system with rear mounted anchors holding the panel clips in place or a modulo clip system that fastens clips to special machined edges on our panels.

For example, in a typical back-ventilated rainscreen system, horizontal rails are attached to vertical L profiles and wall brackets. Then, the phenolic wall cladding hangs on the rails utilizing anchors embedded in the back of the panels.

Concealed fastening systems typically cost more, require more skill, and take more time to install.

Examples of Concealed Fastening Systems

The renovation of the Student Union at Rose-Hulman Institute of Technology in Terre Haute, Indiana, included Fundermax Max Compact Exterior phenolic panels with a woodgrain decor and a concealed fastening system.

This mixed-use building in Saalfenden, Austria, utilized Max Compact Exterior phenolic panels with Fundermax Authentic decor and a concealed fastening system.

Benefits of Exposed and Concealed Fastening Systems

There are benefits to both exposed and concealed options. Choosing the best system will depend on the design specifications and budget allocation for your particular project.

Design Flexibility

Exposed Fasteners

-

The color-matched screws and rivets used to attach the panels to the substructure blend easily with the cladding façade.

-

Exposed fastener systems can achieve high panel yield, which reduces waste and maximizes budget.

-

Easy panel removal for access to the wall behind

Concealed Fasteners

-

Concealed fastener systems provide designs with no visible fasteners for the phenolic cladding panels.

-

By hiding the fastening points, designers have maximum design freedom.

Competitive Pricing

Exposed Fasteners

-

The Fundermax exposed fastening system is competitively priced compared to concealed.

-

Architects are sometimes wary of exposed fastening systems because they worry about the appearance of fasteners and possible design impact. However, it’s helpful to realize that screws or rivets can really only be seen up close; from a distance, they are virtually invisible.

-

With the ability to blend the screws or rivets into the appearance of the phenolic panels, using an exposed fastening system still gives the designer freedom to create while coming in at a lower price point.

Fundermax Modulo Fastening System

-

Our Modulo plank fastening system employs a concealed fastening method at exposed fastening prices. Modulo utilizes a hidden clip system installed with routed edges in an 8mm thick panel.

-

Recall that in concealed fastener systems, the price climbs higher because of the additional cost of all the pieces and the labor to install them. However, Modulo is more affordable because it offers a concealed look without the cost of additional pieces.

-

Ideal for linear designs and plank aesthetics

This Texas high school used Max Compact Exterior phenolic panels with an oak woodgrain decor. They leveraged the Fundermax Modulo fastening system to achieve the concealed fastener aesthetic at an exposed fastener price point.

This elementary school in Massachusetts utilized Fundermax Max Compact Exterior phenolic panels with our Tyrol Pine woodgrain decor and maximized their budget with our Modulo fastening system.

As a globally trusted, sustainable phenolic panel manufacturer, Fundermax has seen a lot over the years, and we know there are many manufacturers you may be considering.

So, we created a resource to help you identify the best option for your project. Architects can compare Fundermax panels and fastening options to others on the market by downloading our newly updated Phenolic Panel Comparison eBook.