.png)

Different Applications of Exterior & Interior Phenolic Panels

Phenolic, also known as high-pressure laminate, panels are among the most newly innovative architectural products available today with an anticipated trajectory path to rise within the market. Industries like construction, education, laboratory, transportation, and defense are choosing phenolic panels due to their durability and sustainability.

When used in interior and exterior projects, phenolic panels can replace steel and wood designs due to their flexibility and versatility. Crafted specifically to allow you unlimited design freedom, phenolic wall panel systems provide options for architects and designers globally.

While phenolic panels are most commonly used as interior and exterior cladding, they still offer several unique applications that are not as normally recognized. Below we will go over all of the different applications of exterior and interior phenolic panels as well as the benefits of choosing them.

Types of Exterior Phenolic Panel Applications

It comes as no surprise that such a versatile material has begun to rise in the construction industry. Exterior phenolic panel applications can be used in facades, soffits, balconies, and sunshades. Many people enjoy seeing textured furniture, which uses exterior phenolic panels to add some personality to the pieces.

The most egregious problem with wood is the need for constant maintenance. Even treated and sealed wood has a short lifespan when compared to other materials such as phenolic panels.

Our Exterior Phenolic Panel Comparison FREE eBook gives you essential differentiations among phenolic panel manufacturers and their exterior phenolic wall panels.

Several exterior applications that you will tend to see are:

Balconies

Balconies

Exterior balcony materials need to be able to stand up to the elements at a height. Phenolic panels are durable, making them ideal for dealing with the buffeting winds at the top of a tall building. They're also scratch and impact-resistant, allowing for everyday use without worrying about damaging the finish. When you're that high up off the ground, UV damage is a concern. Luckily, Phenolic panels are built to handle direct UV exposure and keep their vibrant, rich color and texture. Our Lockhart Stadium Case Study explains why Project Architect, Jaime Ruiz, choose Fundermax's phenolic panels to withstand the persistent wind, heat, and humidity of Florida. These panels are a high-quality, code-compliant material that makes sense to use in balcony construction.

Sunshades

Sunshades

What sets phenolic panels apart from other sunshades is their resilience to UV damage. Thanks to its construction, UV rays don't cause the color and texture of these panels to fade. The result is a vibrant finish that lasts for years without needing to be replaced. It does help that phenolic panels can be used in a curved design and are scratch and impact-resistant, allowing your sunshades to protect your windows from more than just sunlight. Flexible design elements make it a versatile and aesthetic choice for building owners.

Outdoor Furniture

Outdoor Furniture

One of the most prevalent problems building owners encounter with exterior furniture is how badly they deal with the elements. Phenolic panels are naturally weather-resistant and keep their vibrant colors, no matter how long they've been exposed to the sun. The added benefit of being graffiti resistant makes them attractive to people who don't have the time to monitor what's going on with their outside furniture continually. Combined with its natural mechanical strength, phenolic outdoor furniture is an ideal exterior solution.

Types of Interior Phenolic Panel Applications

Interior phenolic panel applications can be used for furniture, wall lining, lockers, washroom partitioning, and even laboratory work surfaces. Our Max Resistance2 material is a lab-grade phenolic that provides a solid level of heat resistance with no discoloration, blistering, or cracking up to 180oF.

Phenolic panels aren't just a great lightweight material with flexible texture options for décor. They are entirely sustainable, and their manufacture utilizes far fewer emissions than other comparative materials such as plastics or wood. High-traffic areas could also benefit from interior wall cladding. Commonly used interior Phenolic panels are indoor furniture, bathroom partitions, and lab surfaces.

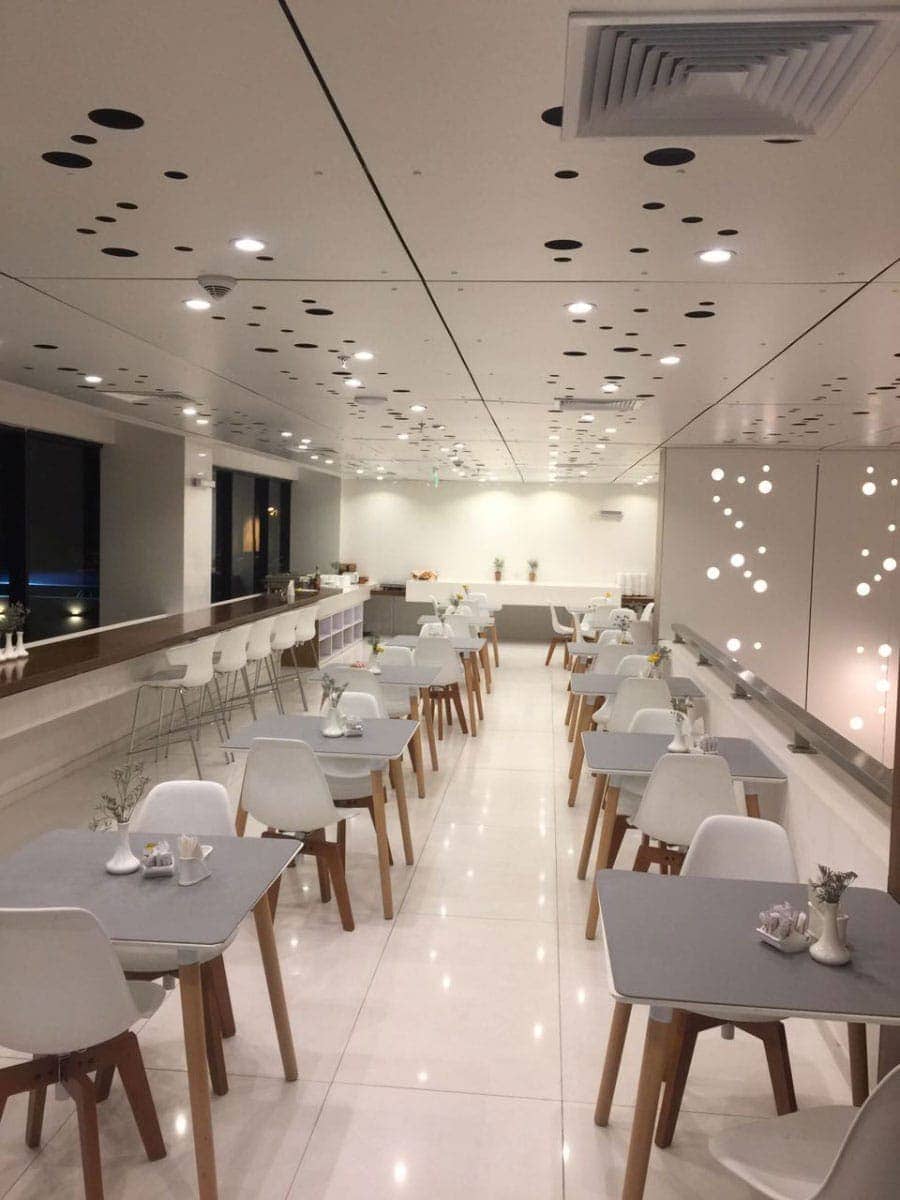

Indoor Furniture

Phenolic panels are mechanically resilient and can stand up to both physical and environmental stresses. They are impact and scratch-resistant, making them ideal for interior furniture used in an everyday setting.

The added benefit of being UV-resistant means that you can place your furniture anywhere you please, without worrying about the color or texture fading. Phenolic panels are naturally solvent and moisture-resistant, making them ideal for any surface that may regularly face these issues. The fact that it's easy to clean is just a bonus.

Phenolic panels offer an excellent option for people who want patterned finishes that complement their interior décor but also want a resilient surface for everyday use.

Bathroom Partitions

Bathroom partitions need to be moisture resistant, making phenolic panels an attractive material for use in these situations. Additionally, thanks to the ability to print on these panels, you can add to the interior décor within your washroom space.

Impact and scratch-resistant surfaces can stand up to all the pressures of use in a public or private bathroom. Graffiti resistance also adds to the draw of using these panels as partitions. Thanks to its lightweight construction, it's also easy to install, making it an excellent option for companies that need a flexible yet durable solution for their washroom separators.

Lab Surfaces

Laboratories tend to have high requirements for their countertop surfaces and phenolic panels check all the boxes. Phenolic panels come with scratch, heat, stain, and chemical resistance built into the material. The surfaces are anti-bacterial and are easy to clean. The high durability of the material, combined with its massive range of colors and textures, allows it to easily fit into any laboratory.

Benefits of Choosing Phenolic Panels

As technology gets better, building materials will begin to display more flexibility and resilience. Phenolic panels are a perfect example of this evolution.

They are a strictly better choice for exterior applications than traditional materials such as wood. They also provide a safe and eco-friendly material for interior applications such as countertops and dividers. There's a lot of factors to consider when choosing phenolic panels for your project. Contact Fundermax to learn more about the different ways our phenolic panels could be right for your project and to order free samples.